- Electro-Coagulation Systems

This cutting-edge Eco-solution was developed in collaboration with our partner E-Watts. Our systems represent the pinnacle of eco-friendly removal heavy metals, organic matters, and approach high effective disinfection technology and recycling the rejected water setting new standards for efficiency sustainability and safety Offerings and the volume of water treatment could be from few m3/h to thousands of m3 /h:

- Soluble salt reduction/minimization

- Enhance the longevity of RO membranes to triple their operational lifespan.

- Removal of phosphates, Sulphur, Sulphates, Silica, etc.

- Decrease the COD and enhance the removal of coagulable Nitrogenous Compounds.

- Reduce energy consumption by 20-30%.

- Eco-friendly solutions that reduce your carbon footprint.

- Cost–effective and efficient operations.

- Customizable options to meet specific needs.

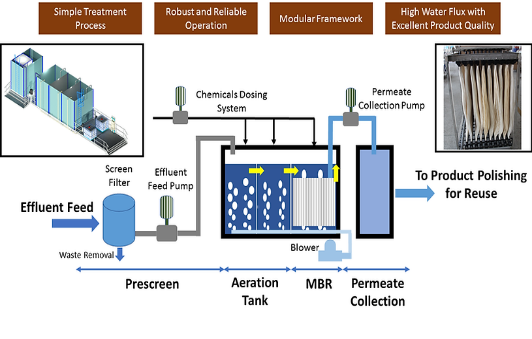

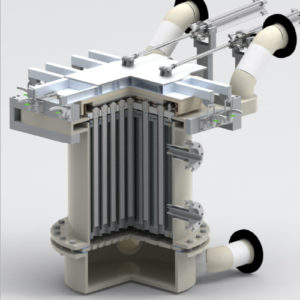

- Membrane Bioreactor

The Membrane Bioreactor (MBR) technology, a pioneering approach in wastewater treatment, merges the traditional activated sludge method with advanced membrane filtration. This innovative process is particularly adept at handling both ultrafiltration (UF) and microfiltration (MF) tasks, making it a cornerstone for modern wastewater management solutions.

A significant leap in MBR technology was achieved when the concept of submerging membranes directly within the bioreactor was introduced. This approach, vastly preferred for its efficiency, especially in treating domestic wastewater, eliminates the need for external separation devices. Submerged MBR systems, characterized by their in-situ membrane immersion, utilize coarse bubble aeration to stimulate mixing and reduce membrane fouling. The introduction of aeration not only helps keep solids suspended but also ensures the membrane surfaces are clean and oxygen is adequately supplied to the biomass. This dual function enhances biodegradability and cell synthesis, marking a substantial improvement in the system’s overall performance.

Submerged MBR configurations, by fostering high biomass concentration with Mixed Liquor Suspended Solids (MLSS) levels ranging from 8000 to 10000 ppm, offer several key advantages over conventional treatment methods. These include the production of exceptionally high-quality effluent, adherence to stringent international discharge standards, and the flexibility to independently control Hydraulic Retention Time (HRT) and Sludge Retention Time (SRT). Such control facilitates a more complete reduction of COD and enhances process stability, including nitrification.

Moreover, the MBR technology stands out for its reduced sludge production, ability to treat high-strength wastewater, and smaller footprint by eliminating the need for clarifiers or filters. These systems also minimize the requirements for post-disinfection processes. With recent advancements, cost reductions, and its array of benefits, MBR technology has seen a surge in application across municipal, industrial, and even remote settings, making it a versatile solution for a wide range of wastewater treatment projects.

At DRC-Chemtech, we’re excited to embrace this new wave of membrane technology. By omitting the historical development of MBR and focusing on its current capabilities and advantages, we highlight our commitment to providing innovative, efficient, and effective wastewater treatment solutions. Our approach not only meets the growing environmental and regulatory demands but also aligns with our mission to offer state-of-the-art technologies that benefit our communities.

MBR applications:

- Residential development projects

- Commercial projects

- Mining camps and other remote installations

- Emergency response

- Military installations

- Sports facilities

- Recreation parks

- Schools

- Shopping centers